Pattern Mechanics in Lab 2

| Led by: | Matthias Wangenheim |

| E-Mail: | heidelberger@ids-uni-hannover.de |

| Year: | 2023 |

| Date: | 28-02-23 |

| Duration: | 01.04.2022-31.03.2023 |

Project describtion

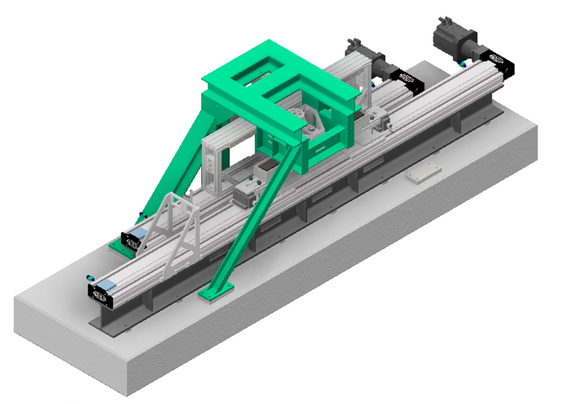

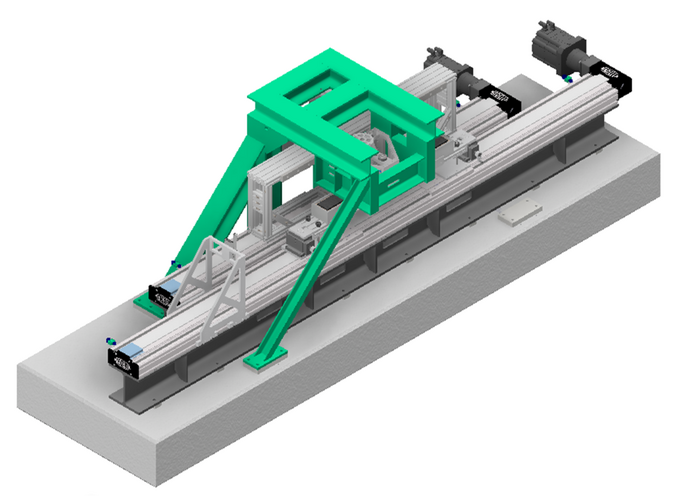

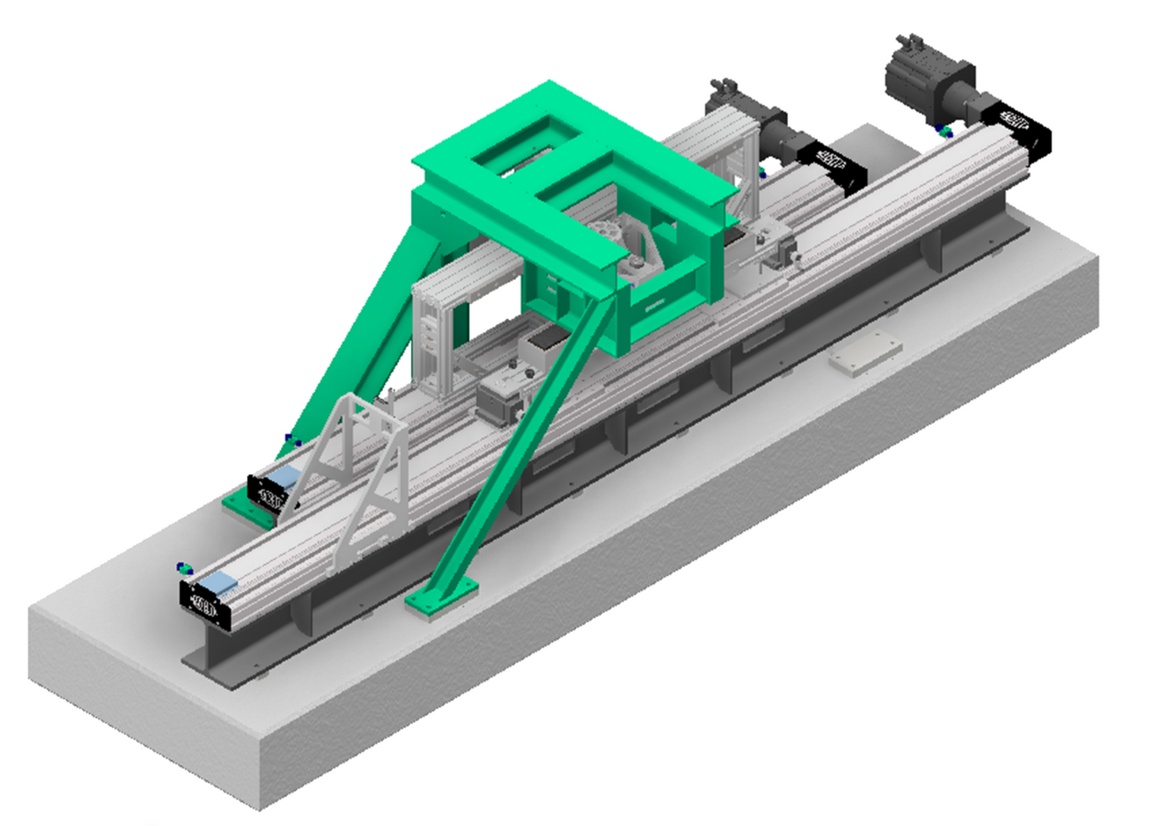

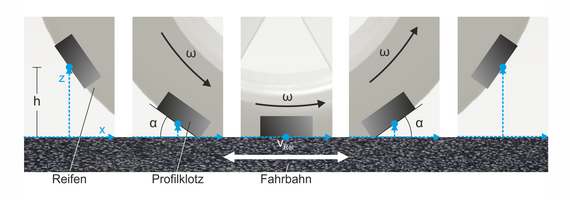

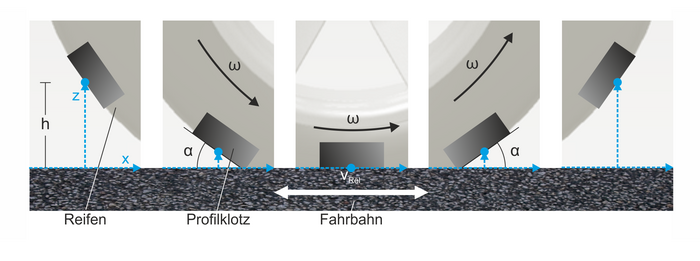

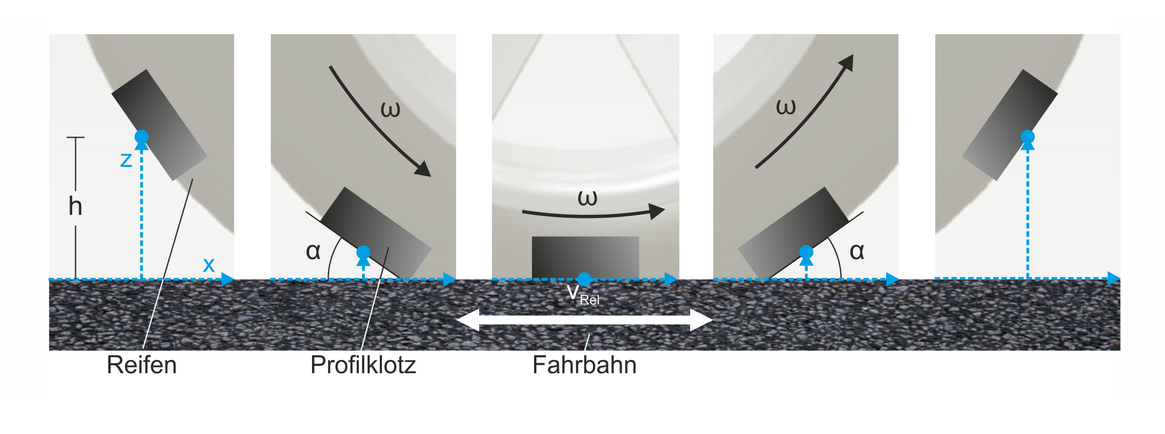

The "Pattern Mechanics in Lab 2" project is a direct successor of the "Pattern Mechanics in Lab" project and is part of a series of research projects at IDS that focus on the mechanisms of rubber, particularly on snow and ice. In order to ensure comparability with outdoor experiments and a high degree of reproducibility, the existing method of snow production was extended so that snow with defined, adjustable and precisely reproducible properties can be produced. Thanks to suitable preparation, the artificially produced snow has the same characteristics as natural snow. The test rig created in the course of the previous RPL project to simulate the rolling motion of a tire tread block on a car tire for a single rubber sample is being used in the current project to develop an improved test method for tread blocks on snow. The aim is to directly predict the expected tire performance. The sliding distances, sliding speeds and loads are based on the specifications of a real tire in order to be able to carry out the tests with parameters that are as close to reality as possible. Thanks to the reproducible rolling motion in the laboratory, the individual mechanisms that lead to force transmission between the tire and the ground can be examined more closely. In addition to the friction between the tread block and the surface in the case of snow, this also includes the penetration of the tread blocks into the ground.

Among other things, it is being investigated how the friction coefficient of tread blocks changes on different surfaces when the blocks are rotated around the vertical axis. For example, when using a sample with three sipes on snow, the resulting coefficient of friction is reduced by almost 40% by rotating the sample. On a dry asphalt road, on the other hand, a correspondingly rotated sample achieves a coefficient of friction that is around 15% higher.